The Art and Science of Manufacturing

The Art and Science of Manufacturing

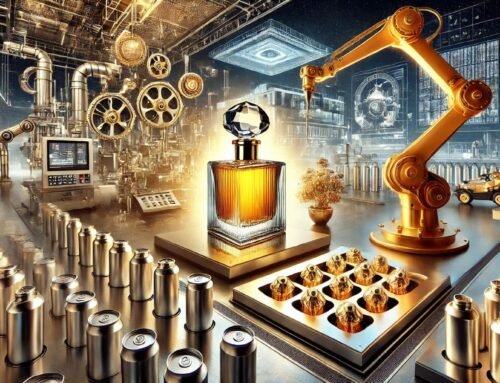

The Art and Science of Perfume Cap and Spray Nozzle Manufacturing

Perfume packaging is an essential aspect of the fragrance industry, influencing both user experience and brand perception. Among the key components of a perfume bottle, the cap and spray nozzle play a crucial role in protecting the fragrance, ensuring proper dispensing, and enhancing the overall aesthetic appeal. The manufacturing process of these components involves precision engineering, high-quality materials, and innovative designs to meet the demands of luxury brands and mass-market fragrances alike.

Materials Used in Perfume Caps and Spray Nozzles

The choice of materials for perfume caps and spray nozzles determines their durability, aesthetic quality, and functionality. Commonly used materials include:

1. Materials for Perfume Caps:

-

Plastic (ABS, PP, or Acrylic): Lightweight and cost-effective, widely used in both luxury and budget-friendly perfumes.

-

Metal (Aluminum, Zamac, or Stainless Steel): Provides a premium feel and is commonly used for high-end fragrances.

-

Wood: Used for eco-friendly and niche perfume brands, adding a natural and artisanal touch.

-

Glass: Occasionally used in premium perfumes for a sophisticated appearance.

2. Materials for Spray Nozzles:

-

Stainless Steel: Offers durability and resistance to corrosion.

-

Aluminum: Lightweight and rust-resistant, commonly used in high-end spray systems.

-

Plastic (POM or PP): Cost-effective and chemically resistant, ensuring smooth spraying.

Manufacturing Process of Perfume Caps and Spray Nozzles

1. Design and Prototyping

Before mass production, designers create 3D models of the caps and nozzles to ensure they match the bottle’s design and functionality. Prototyping is done using CNC machining or 3D printing to test the final look and usability.

2. Material Preparation and Molding

-

Plastic caps and nozzles are manufactured using injection molding, where molten plastic is injected into pre-designed molds and cooled into shape.

-

Metal caps are produced through die-casting, where molten metal is poured into molds to form detailed and embossed designs.

-

Wooden caps are crafted through precision carving and polishing to achieve smooth finishes.

3. Surface Treatment and Finishing

To enhance the durability and aesthetics, various finishing techniques are applied:

-

Electroplating (for metal caps): Adds a shiny, polished, or matte effect.

-

Spray Coating (for plastic caps): Enhances color and texture.

-

UV Coating: Protects the surface from scratches and fading.

-

Lacquering (for wooden caps): Provides a protective, glossy finish.

4. Assembly and Quality Control

Once the components are manufactured, they undergo assembly and testing to ensure they function smoothly:

-

Spray nozzles are fitted with valves to regulate perfume dispensing.

-

Caps undergo fit testing to ensure a snug fit on the bottle.

-

Durability tests are conducted to assess resistance to pressure and leaks.

Innovations in Perfume Cap and Spray Nozzle Manufacturing

The perfume industry constantly evolves, with new innovations enhancing functionality and sustainability:

-

Magnetic Caps: High-end brands now use magnetic closures for a seamless and luxurious experience.

-

Eco-Friendly Biodegradable Caps: Made from plant-based plastics or recyclable materials.

-

Advanced Spray Nozzles: Micro-mist technology ensures a finer, more even spray.

-

Anti-Leak Valves: Prevent evaporation and leakage, preserving the fragrance longer.

Conclusion

The manufacturing of perfume caps and spray nozzles is a highly technical process that balances aesthetics with functionality. With constant innovation in materials, design, and sustainability, manufacturers continue to elevate the sensory and visual experience of fragrances. As the perfume industry grows, the demand for high-quality, sustainable, and innovative packaging solutions will only increase, shaping the future of perfume packaging.